- World-class composites engineers. From the fundamental materials science to the real-world problems of manufacturability, our engineers know composites like few others. You can count on Clearwater engineers to get the most performance out of your parts.

- High-quality manufacturing facility. All composite parts are produced in-house at our facility in Duluth, MN. Our facility is also certified to AS9100D and ISO9001:2015 standards, capable of producing parts for even the most demanding industries like aerospace and defense.

- Outstanding customer service and communication. Based in the US, we’re problem-solvers and hard workers. In an increasingly global composites industry, accessible and adaptable manufacturers can become hard to find. Partner with Clearwater for responsive carbon fiber expertise.

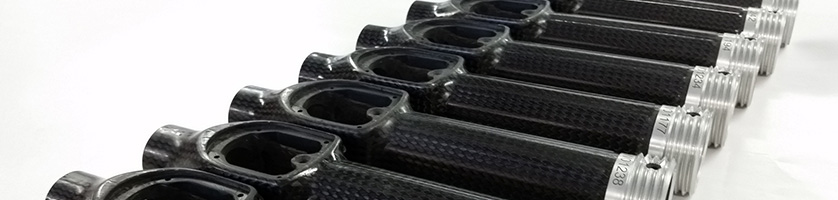

Carbon Fiber Parts

Get in touch with Clearwater Composites today. You will receive a prompt response!

Composite Process Methods

- Roll Wrapping

- Resin Transfer Molding (RTM)

- Bladder Molding

- Vacuum Bagging

- Compression Molding

- Trapped Rubber Molding

- Other Proprietary Composites Processes

Secondary Operations

- CNC Machining

- Centerless Grinding

- Complex Bonded Assemblies

- Finishing and Painting

Materials

- Carbon fiber

- Fiberglass – E-glass and S-glass

- Aramid

- Other fibers

- Thermoset composite

- Thermoplastic composites