Also, take care around electronics; the conductive nature of carbon can easily fry nearby computers, laptops, and other devices. With this in mind, ensure proper precaution is taken prior to making your first cut. It may be worth covering or moving any devices in the area.

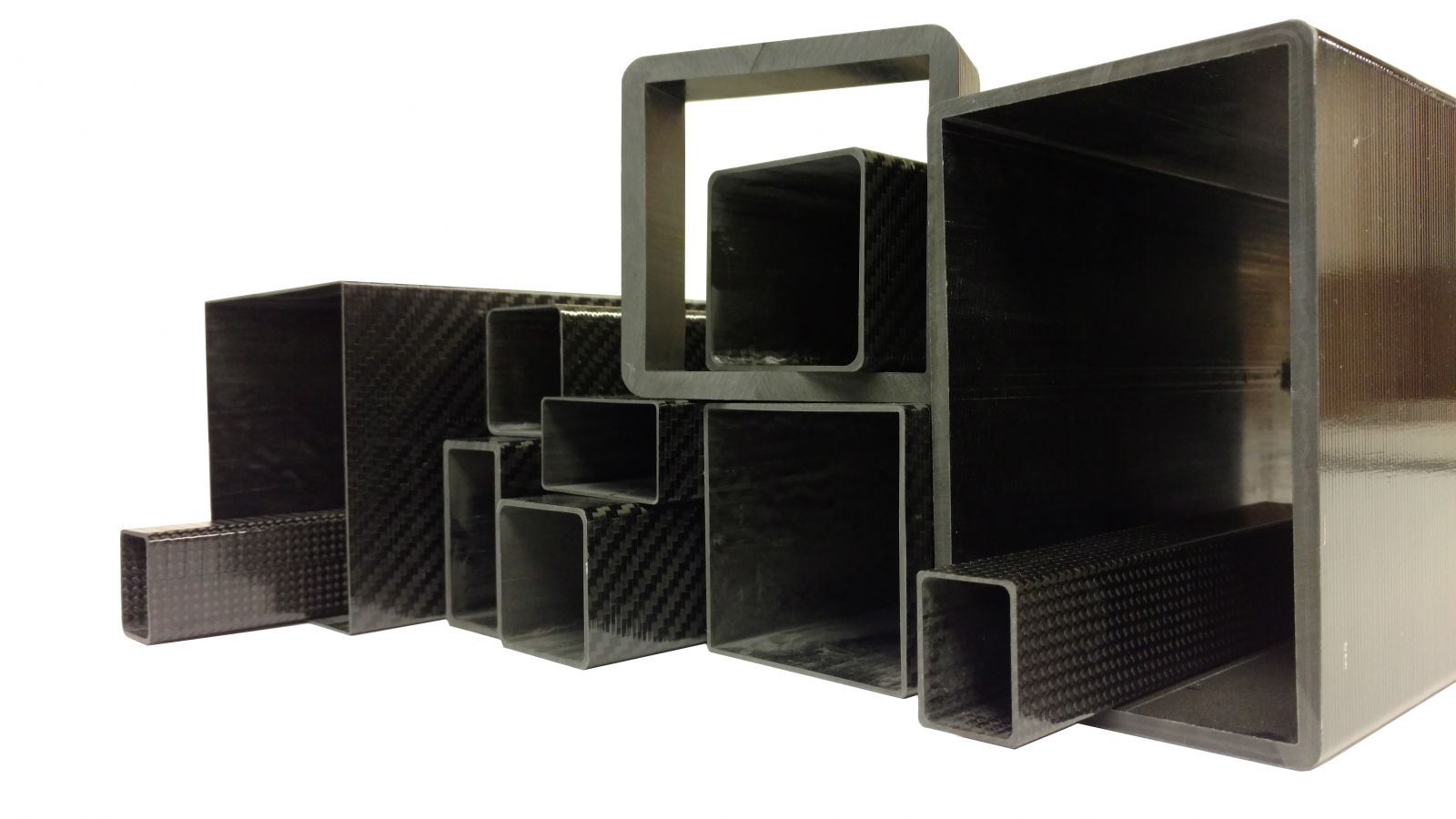

Cutting carbon fiber tubing can be difficult. If done incorrectly, the tube can be damaged beyond repair in the blink of an eye. This article will break down the steps on how to cut carbon fiber tubes.

If you would like us to cut the tubes for you, contact our sales team of carbon fiber experts for an estimate.

- PPE: Safety glasses, dust collection, hearing & respiratory protection.

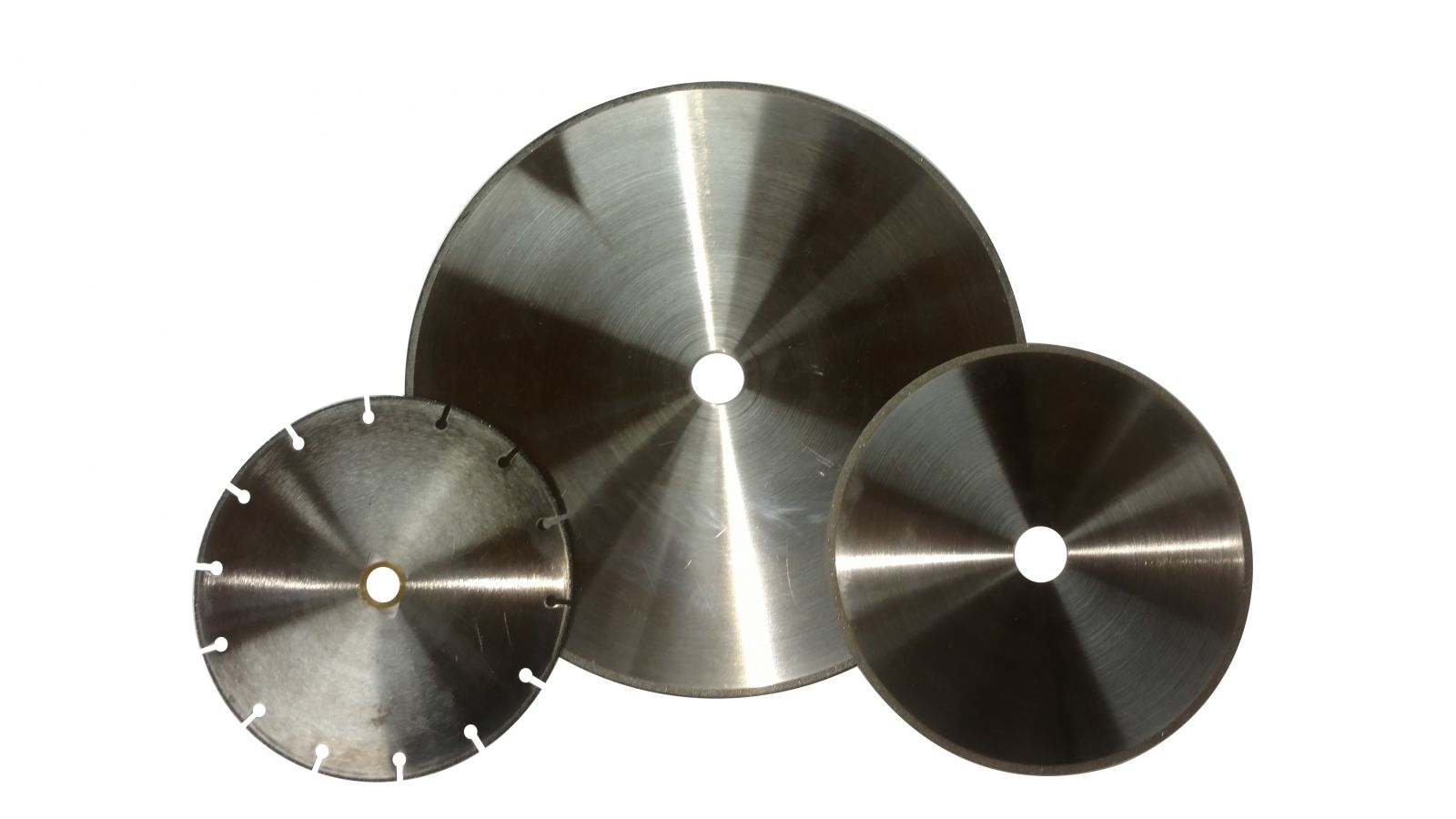

- Cutting: Diamond coated abrasive cut-off blade.

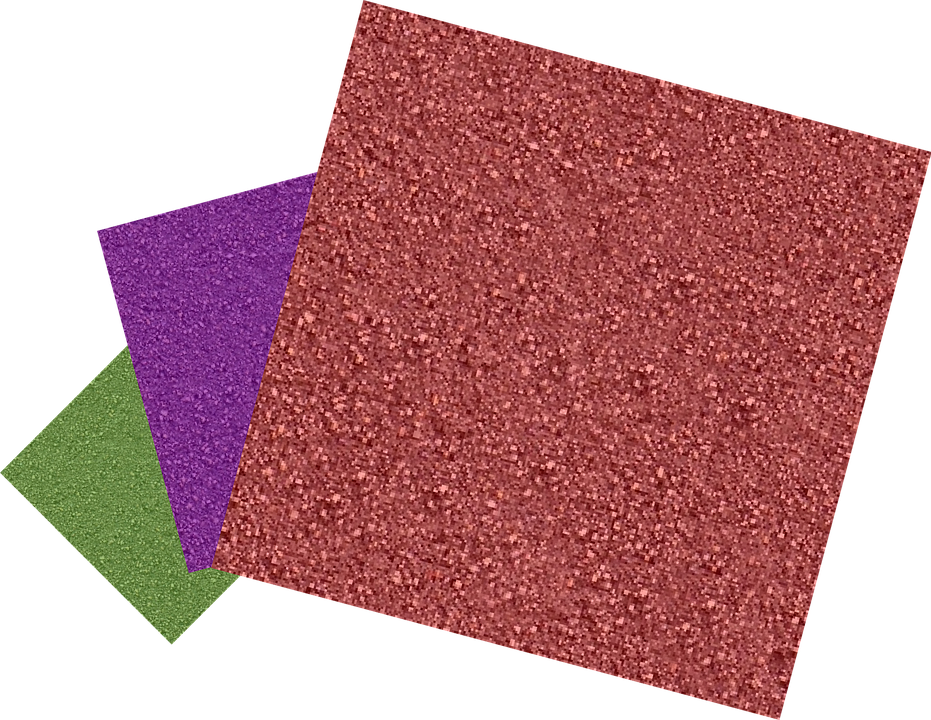

- Finishing: Sand paper or other abrasive surfaces

This is the most important part. When cutting composites, it is ideal to use a diamond coated abrasive cut-off blade rather than a toothed blade. Teeth can catch the fibers and tear the material resulting in splintering or delamination.Thicker tubes may generate enough heat to re-activate the epoxy causing the blade to “gum-up”.To prevent “gumming”, cool the cutting surface/blade. Using a segmented blade will help reduce heat. Another option is to actively cool by using a wet saw.

An unsupported tube can result in a “burred” edge. This is caused by one side of the tube moving before the cut is finished.Burrs are typically found on the “drop” section. If multiple sections are being cut out of a tube, it is crucial to support and brace both the cut end and the drop end of the tube.

We often get questions on how to cut carbon fiber tubes. Cutting carbon fiber tubing can be difficult if done incorrectly. Today we will show you 3 common issues and the best way to avoid/fix them.

Delamination: Delamination often occurs when cutting unidirectional tubing. Individual filaments or tows tear away from the rest of the composite.Fix: Slow down, take your time while cutting the tube. Let the material grind away at its own pace. Do not force the blade through the tube. If you are still having issues, try using a thinner blade with finer grit.

Burring: Burring occurs at the last second of cutting. This is due to lack of support/securing one, or both, ends of the tube. The carbon fiber tube begins to break away as the final filaments are cut.Fix: Secure both ends of the tube. Use a weight or clamp to ensure minimal movement throughout the cut.

Overheating:Overheating is often result of intense friction. It is often occurs when cutting thicker walled carbon fiber tubes. The resin reaches its TG and begins to flow.Fix: Reduce heat. Here we have a few options. Either slow down to reduce friction or use liquid as a coolant to keep the heat down. If you are cutting multiple tubes it may save time to use a wet saw.

Overheating:Overheating is often result of intense friction. It is often occurs when cutting thicker walled carbon fiber tubes. The resin reaches its TG and begins to flow.

Fix: Reduce heat. Here we have a few options. Either slow down to reduce friction or use liquid as a coolant to keep the heat down. If you are cutting multiple tubes it may save time to use a wet saw.

(Bonus) Fraying:When cutting aramid or carbon/aramid hybrid tubes the cut edge is often “fuzzy”. Aramid is a difficult material to cut, it is very tough. The Fuzz is result of the aramid tearing instead of cutting.

Fix: After cutting “touch-up” the tube with sand paper. It may not be a perfect edge but it will help.

Though there are many other problems you may encounter when cutting carbon fiber, these are the most common. We have been cutting carbon fiber tubing for years, and have experienced every issue you can think of. If you are having trouble feel free to reach out, we can help.